Although the die-casting mold manufacturing was a departure from absolutely inexperience, we introduced advanced system like the three-dimensional CAD / CAM as early as possible, and then we worked on the latest digital technology in the mold field that was said to be craftsmanship.

Since then, over 20 years, we’ve continued to make efforts every day so that we can offer the best molds to our customers, taking advantage of the knowledge learned from production experience of more than 800.

Full-time staff will make arrangement with customers detailed specifications of the products.

In addition, we will respond flexibly to all forms of exchange of data with customers.

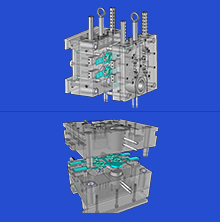

We will design the mold based on the material drawing received from the customer.

We will create part drawings and parts lists from this mold data and make mold models.

n parallel with mold design, we will model the die design for material and work with 3D CAD.

We support CAD data written in various formats.

When the structure is complicated, we may model the entire die including cooling holes and hydraulic piping etc. By doing this, suppression of trouble and optimization of design are carried out.

- Calculation of NC data by CAM, and cutting simulation

- Various machining centers are installed from die engraving to electrode machining.

In addition, our machining centers are all operating by a command (DNC7) from a host computer, so unmanned operation for 24 hours is possible even for processing requiring a long time such as a big product.

- Electric machining is also carried out with wire cutting, high-capacity electric discharge machines and high-speed gloss electric discharge machines.

Since all the data of the mold manufactured by our company are kept carefully, it is possible to respond quickly to sudden repair and parts arrangement.

Also, since information is recorded for every single mold, we also grasp what kind of process the repair or remodeling was done in the past.

| Maker | Model name | Type | Number of machines |

Processing capacity and dimensions |

|---|---|---|---|---|

| Makino Milling Machine Co., Ltd | FNC1710-A30 | Vertical machining center | 1 | 1700×1000×700 |

| Makino Milling Machine Co., Ltd | V33i Graphite | Vertical machining center | 1 | 650×450×350 |

| Yasuda Kogyo Co., Ltd. | YBM950V | Vertical machining center | 2 | 900×500×350 |

| DMG Mori Seiki Co., Ltd. | DMC100UduoBLOCK | 5 axis machining center | 1 | 1000×1250×1000 |

| JTEKT Corporation | FH-80S | Horizontal machining center | 1 | 1350×1150×1150 |

| Makino Milling Machine Co., Ltd. | NC type carving electric discharge | EDNC85 | 1 | 800×500×350 |

| Makino Milling Machine Co., Ltd. | NC type carving high speed gloss electric discharge machine | EDNC43S | 1 | 450×300×320 |

| Mitsubishi Electric Corporation | Wire electric discharge machine | MV-2400R | 1 | 600×400×310 |

| Okamoto Machine Tool Works, Ltd. | Surface grinding machine | PSG84 | 1 | 800×400 |

| Metrotec Corporation | CMM | RS30 DCC | 1 | 1000×750×625 |

| Maker | Model name | Type | Number of machines |

Processing capacity and dimensions |

|---|---|---|---|---|

| NDES | Space/E Draw | 2D CAD | 1 | PC WorkStation |

| NDES | Space/E Modeler,CAM | 3D CAD/CAM | 1 | PC WorkStation |

| SIEMENS | UGNX | 3D CAD | 1 | PC WorkStation |

| Makino Milling Machine Co., Ltd. | FF/CAM | 3D CAM | 1 | PC WorkStation |

| VERO | VISI-CAD/CAM | 3D CAD/5axisCAM | 1 | PC WorkStation |

| VERO | VISI-CAD Mould | 3D CAD | 1 | PC WorkStation |